Charpy Test

The Charpy impact test is a crucial method used to measure the toughness and impact resistance of materials, particularly metals. It’s commonly employed in material science and engineering to assess how a material behaves under sudden impact. Here’s how it works:

- Preparation:

- A small, rectangular sample of the material is prepared with a specific notch (a V-shaped or U-shaped cut) in the middle. This notch is designed to simulate stress concentrations, making it easier to study the material’s fracture characteristics.

- Test Setup:

- The sample is placed horizontally on a support fixture within the Charpy testing machine, with the notch facing away from the pendulum’s impact.

- Execution:

- Having cooled or heated the samples to the required temperature, a heavy pendulum is released from a predetermined height, swinging down to strike the sample on the side opposite the notch.

- The energy absorbed by the material during fracture is measured. This is determined by the difference in the pendulum’s potential energy before and after the impact.

- Key Results:

- Absorbed Energy: The amount of energy required to break the material, usually measured in joules. It indicates the material’s toughness.

- Ductile or Brittle Behavior: By observing the fracture surface, engineers can determine if the material behaves in a ductile (stretches before breaking) or brittle (snaps suddenly) manner.

- Applications:

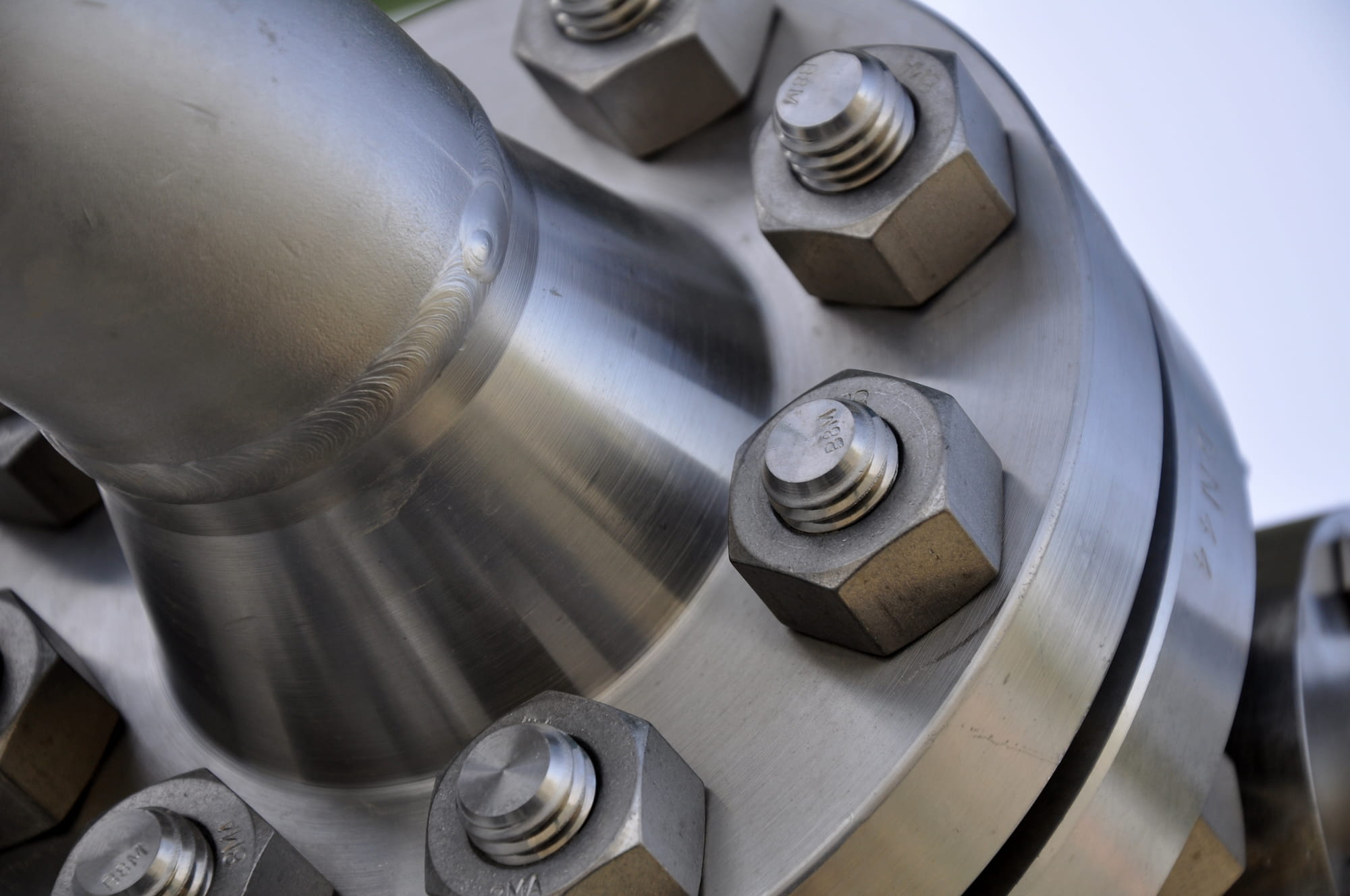

- This test is particularly important for materials used in construction, pipelines, and pressure vessels, where toughness is critical, especially at low temperatures.

It’s a quick and effective way to evaluate how a material might perform in real-world conditions, particularly when subjected to sudden or dynamic forces.