Shear Testing

Shear testing is a method used to evaluate a material’s behaviour when subjected to forces that act parallel to its surface, causing layers of the material to slide against each other. It provides insights into a material’s shear strength, which is its ability to resist these forces before failing. Here’s how it works:

1. Purpose:

- Shear testing is used to measure the maximum shear stress a material can withstand before yielding or fracturing.

2. Test Setup:

- A test specimen, often rectangular or cylindrical, is prepared and mounted in a shear testing machine.

- The machine applies a controlled force parallel to the material’s surface or along a defined shear plane.

3. Execution:

- The force is gradually increased until the material yields, deforms, or fractures along the shear plane.

- During the test, the applied force and the displacement of the material are recorded.

4. Key Measurements:

- Shear Strength: The maximum shear stress the material can sustain.

- Shear Modulus: Measures the stiffness of the material under shear forces.

- Shear Strain: The amount of deformation experienced before failure.

5. Applications:

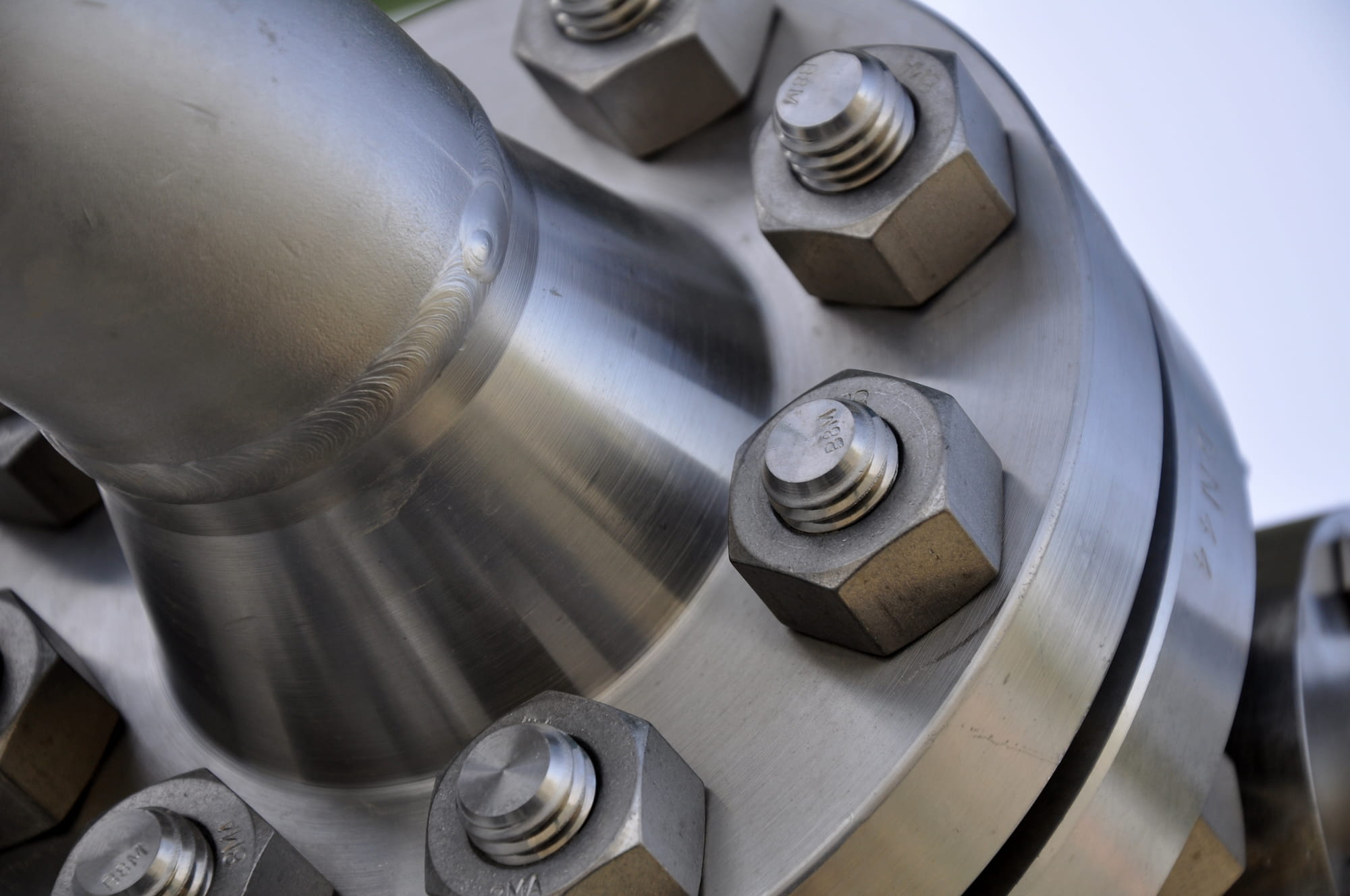

- Used in mechanical, civil, and aerospace engineering to design structures and components, such as beams, bolts, rivets, and welds.

Shear testing is critical for ensuring materials and structures can handle the shear forces they are exposed to in real-world applications.