Wedge Load Testing

Wedge load testing is a specialized test used to evaluate the structural integrity and load-bearing capacity of fasteners, such as bolts or studs, under tensile stress. It ensures that the fasteners can handle specific loads without failure. Here’s an overview of the process:

1. Purpose:

- The test determines the tensile strength of fasteners, especially high-strength bolts, and assesses their ability to handle axial loads under real-world conditions.

- It helps detect manufacturing defects like improper heat treatment or material inconsistencies.

2. Test Setup:

- A wedge is used to create an angular displacement at the underside of the fastener’s head during the test.

- The fastener is secured in a tensile testing machine, with the wedge placed under the bolt head to simulate worst-case loading scenarios.

3. Execution:

- A tensile force is applied to the fastener while the wedge creates additional stress at the head and shank junction.

- The load is increased gradually until the fastener fractures or a specified proof load is reached.

4. Key Results:

- Ultimate Tensile Strength: The maximum load the fastener can bear before failing.

- Fracture Location: Observations of where and how the fastener fails help assess its design and manufacturing quality.

- Stress Distribution: The test checks whether the fastener can handle uneven stress caused by angular forces.

5. Applications:

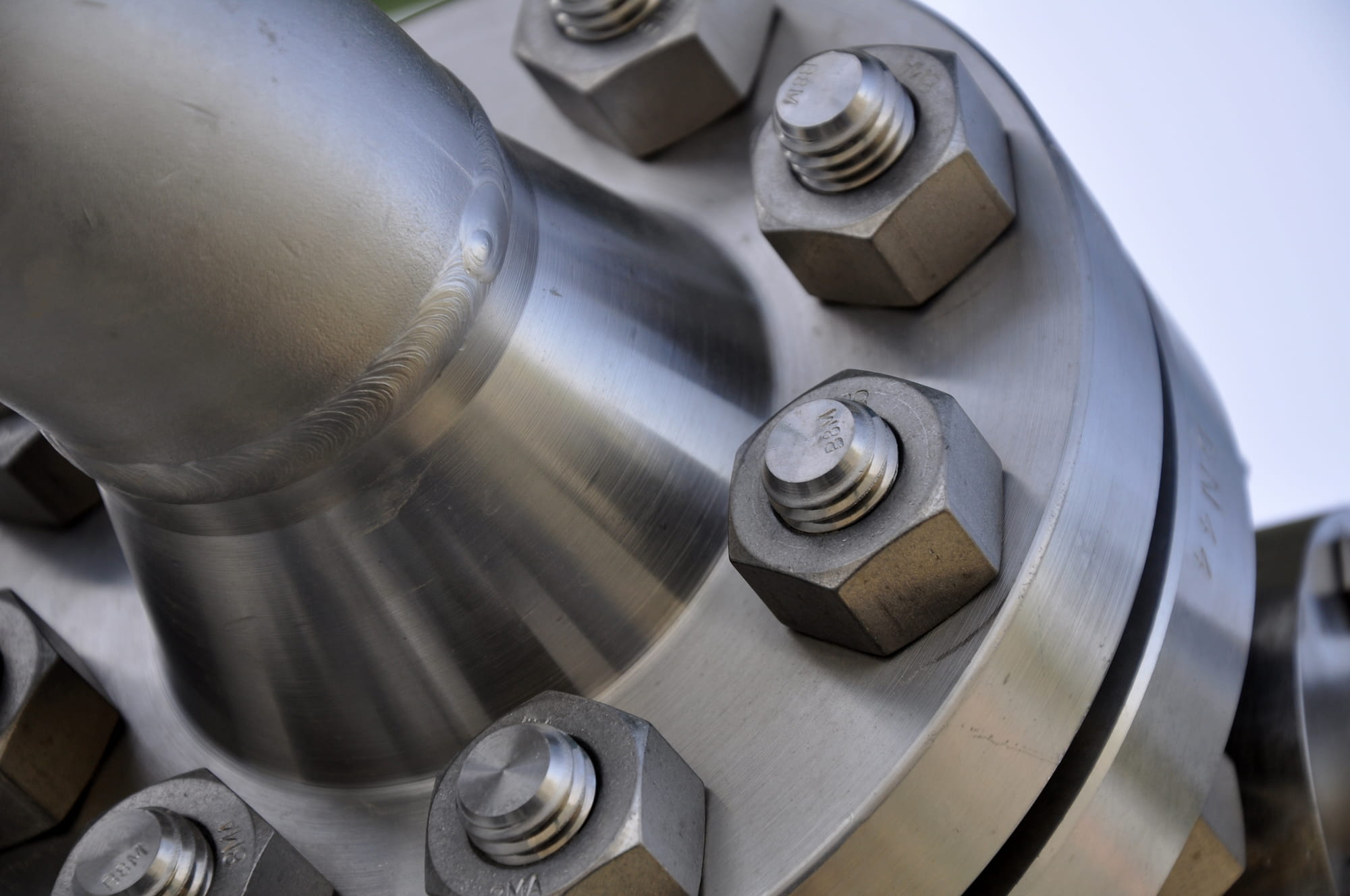

- Commonly used in industries like construction, automotive, and aerospace to ensure the safety and reliability of critical fasteners.

- Helps in selecting or certifying fasteners for high-stress environments.